Home » Corrugators » Small-sized corrugators » UC 58 vario

UC 58 vario

The versatile one

precise - flexible - versatile

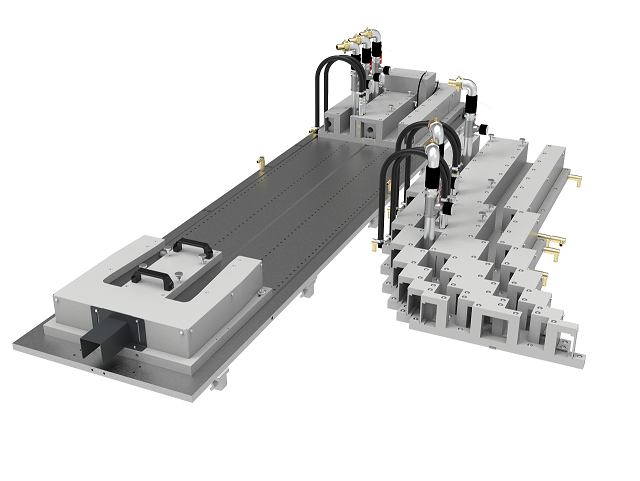

Thanks to the forward-looking vario-machine concept, it is very quick and easy to adjust the number of mold blocks.

A large number of common products in the automotive and medical sectors can be produced extremely economically on this corrugator. By using the high-temperature version, materials such as fluoroplastics that require a mold block temperature of over 100°C can also be processed excellently.

The uniform operating concept for small corrugators guarantees an optimal utilisation of the corrugators and the production staff. The new innovative design allows improved accessibility to relevant components.

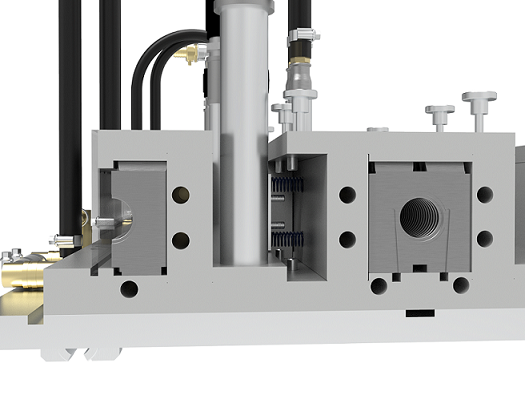

Perfected quality of the end product due to precisely manufactured mold blocks and their guidance in the spring loaded middle channel. Narrow curve radius, short dies, low back pressure and higher throughput provide more efficiency and flexibility, also concerning the choice of material.

- Each corrugation can be supplied individually with vacuum

- Free positioning of vacuum holes for mold blocks possible

- Extension modules are available with and without vacuum

- Precise speed variation

- Management of cuff process parameters

- Adjustment of forming air via proportional valves

- Excellent suitability of the hightemperature version for technical plastics such as fluorpolymers

- Precise control of the mold block temperature by means of an external heating/cooling unit

- Special hardening process and surface treatment for mold block carriage and modules

- Electronic control of process air

- Measurement of all vacuum parameters

- Measurement of water inlet and outlet pressures

Extendable mold chain length

The corrugator can be extended by adding further middle- and return channel modules in steps of one mold block. This makes it very easy to adapt the mold block chain length to the end product.

Spring-loaded middle channel

One UNICOR innovation is the spring-loaded middle channel – this is the only way to produce with zero middle channel tolerance. Another advantage of this feature is the easy handling during the production of pipe-in-pipe or pre-wired products.

Applications

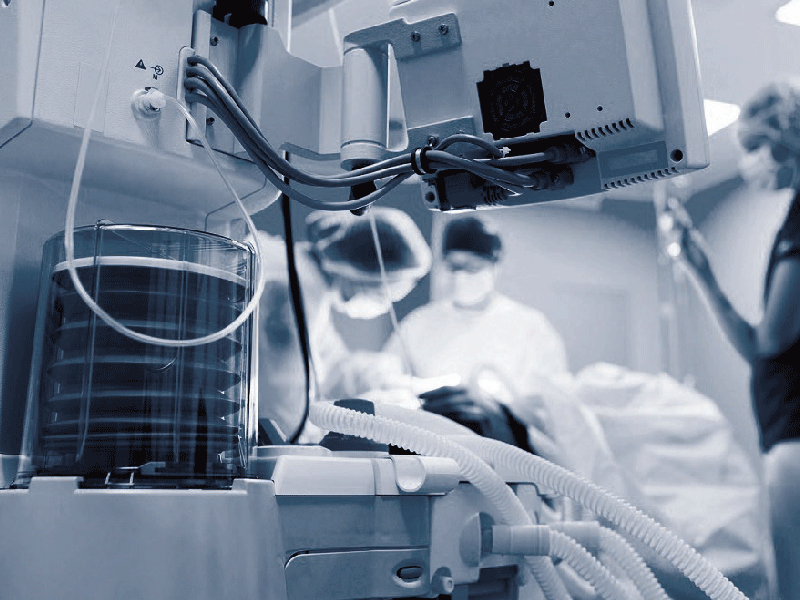

Medical

Flexible, corrugated plastic pipes are often used on medical respirators as well as on devices for anaesthesia and sleep apnoea. Other applications include urine catheters and mobile respirators for firefighters. Special applications where flexibility and dimensional stability are important are also a grateful environment for our corrugated tubes.

Pipe in pipe

Corrugated pipes are used as a protection for cold and hot water pipes as well as for underfloor heating pipes. The medium-carrying pipe is unwound from prefabricated pipe drums or fed inline to the corrugated pipe by means of a special feeding process. This results in efficiency and cost optimization in the overall manufacturing process.