Home » Corrugators

Corrugators

Overview of the UNICOR series

Flexible high-performance corrugators even for smallest diameters

Entry into corrugated pipe production or specialization in premium-quality corrugated pipes for automotive sector and medical science – that’s what the UNICOR corrugators of the small series stand for. A wide product range and a robust construction represent a sustainable investment – low maintenance effort and lower wearing are benchmarks in our way of thinking. Especially in the small series, the compact corrugators impress with the UNICOR water cooling. Constant process temperature ensures the premium UNICOR quality with constant shrinkage values and high output rates. Based on the optionally available Vario technology, the corrugators can be upgraded to a wide range of product requirements at any time.

UNICOR classics – corrugators in the medium machine segment

The generalists of UNICOR are particularly convincing with their robust and compact design. Thanks to the direct mold block cooling of UNICOR, high outputs with high pipe quality can be produced on the machine. Cost and noise optimization can be achieved by an efficient and energy-saving vacuum system being supported by speed-controlled vacuum pumps. The high quality machine components in use are very reliable and only require low maintenance. Quick-change systems complement the simple handling and increase machine availability.

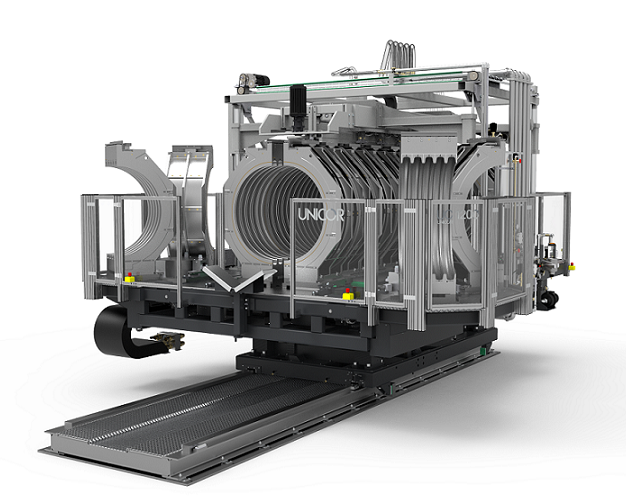

Shuttle Principle offers unequalled opportunities – the UNICOR large-scale corrugators

Our Shuttle Corrugators complete the series upwards. This model series stands for a small number of mold blocks which are separated in the return channel. The cooling and molding section of the middle channel has been selected in such a way that preferably high outputs can be achieved. Low maintenance effort and low wearing are benchmarks in our way of thinking – also for the large-scale diameters. Based on the innovative and direct UNICOR water cooling which also finds its application in large-scale machines, constant process parameters can be guaranteed for right from the start. This is the continuation of the UNICOR quality requirement with constant shrinkage values and high output speeds. A wide range of product lengths can be easily selected in the control system via the parking station for cuff mold blocks. Retrofitting of the machine is not necessary.