Home » Corrugators » Small-sized corrugators » UC 58

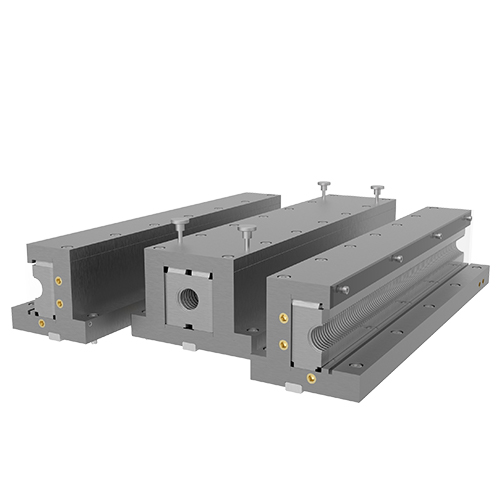

UC 58

The most popular

proven - versatile - efficient

The uniform operating concept for small corrugators guarantees an optimal utilisation of the corrugators and the production staff.

Thanks to the forward-looking machine concept, the cooling capacity can be increased quick and easy.

A large number of common pipe sizes in the field of electrical installation can be produced economically on one machine.

Perfected quality of the end product due to precisely manufactured mold blocks and their guidance. Narrow curve radius, short dies, low back pressure and higher throughput provide more efficiency and flexibility, also concerning the choice of material.

- Each corrugation can be supplied individually with vacuum

- Free positioning of vacuum holes for mold blocks possible

- Easy retrofit of an overpressure corrugator to vacuum forming process

- Central height adjustment for fast positioning of the duo mold blocks

- Powerful drive system for almost all applications, optional also for double wall corrugated pipes

- Highly efficient coolant guidance in the medium and return channel of the corrugator

- High output capacity for common polyolefin materials also in the double wall pipe segment

- Electronic control of process air

- Measurement of all vacuum parameters

- Measurement of water inlet and outlet pressures

- Electrical control of mold temperature

Modular extension of the middle channel

The corrugator can be extended by adding further middle- and return channel modules in steps of 20 or 30 mold blocks. This simplifies increasing the cooling capacity and output of the machine.

Operating panel with swivel arm

All functions can be selected intuitively on the operating panel, which can be positioned ergonomically via the swivel arm. Due to the screen size of 15″ and the new user interface, an excellent overview has been achieved.