Home » Corrugators » Large-sized Corrugators » UC 1200

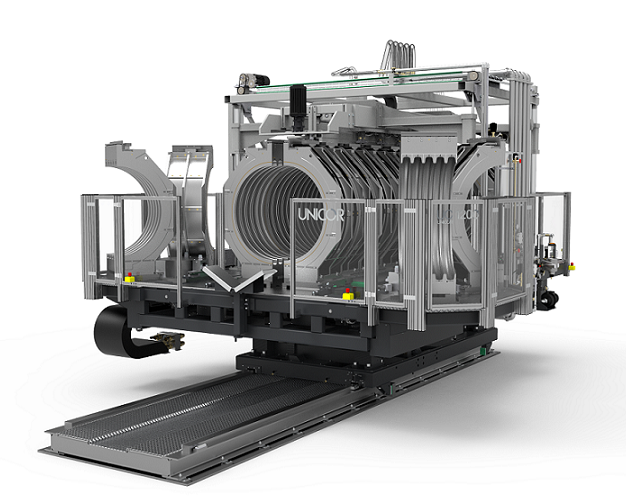

UC 1200

The pioneer

reliable - powerful - efficient

By using the park station, different pipe lengths can be realized by simply changing the parameters without having to rebuild the machine. The control of the corrugator automatically adjusts to the preselected number of forming jaws. This means that different product lengths can be produced with one inline sleeve.

Middle channel length and a stable vacuum process are the main keys to achieve highest output. The shuttle principle and the separation of the mold blocks enable the maximum possible output.

Up to 50% energy savings via a speed-controlled vacuum pump with a connected load of only 35 kW.

Highest quality of profile surface and profile shaping – thus easier processing and higher stability of the corrugated pipes, also with recycled materials. Specially developed die heads with low back pressure and thus higher throughput offer more efficiency and higher flexibility, also in material selection.

- Diameter range from 200 i.d. to 1200 mm o.d.

- Production of all common drainage, sewer and storm water pipes without output reduction

- Compatibility of UC 5XX and UC 800 mold blocks by means of mold block adapter

- Direct-cooled aluminium mold blocks

- Minimal changeover time for mold blocks

- One drive unit for all applications

- Speed regulated vacuum pumps

- Only 20 °C cooling water inlet temperature necessary

- Electronic control of process air

- Registration and recording of all vacuum parameters

- Registration, recording and electrical control of all water inlet and outlet pressures as well as temperatures

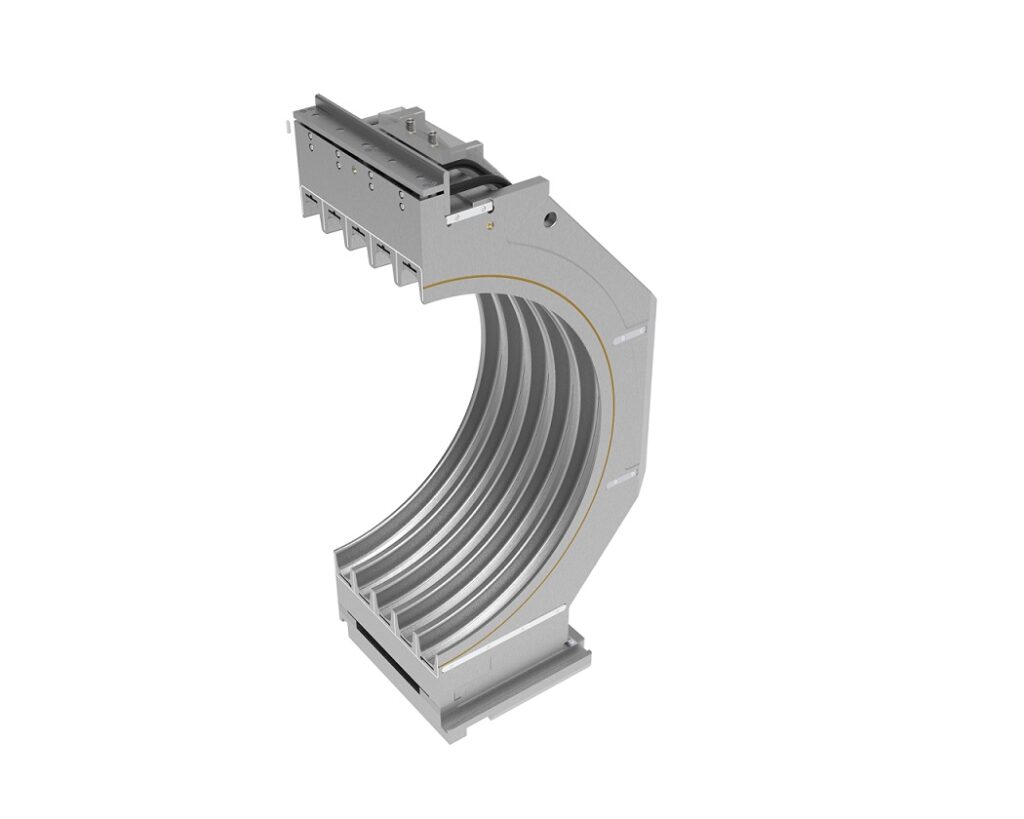

Water cooling of mold blocks

The discontinuous and highly efficient water cooling of the aluminum vacuum forming mold block allows to produce a high quality pipe right from the start of the production. The preselected process parameters are achievable with a very high repeatability.

Parking station

The optionally available parking station makes it easy to add cuff mold blocks to the process. This allows different product lengths with inline cuff.