Insight into Production

UNICOR - Made in Germany - Made in Hassfurt

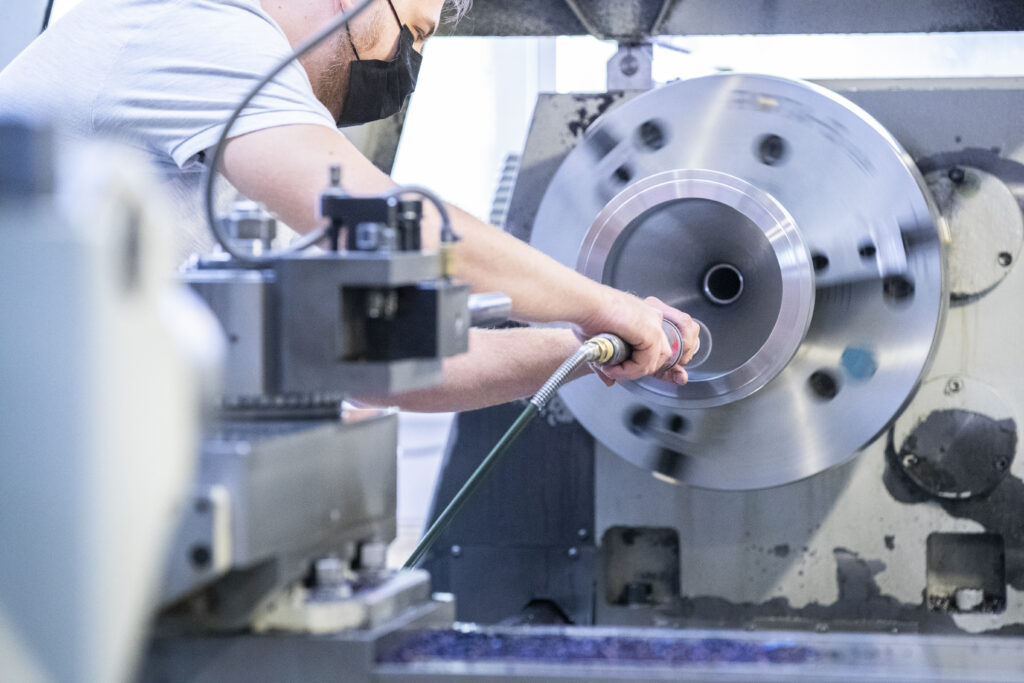

Machining – Drilling – Grinding

Our modern and wide-ranging machine park allows us to efficiently manufacture a huge product portfolio inhouse. We have succeeded excellently in the balancing act between changing customer-specific parts and a standardized product range.

In addition to the production of highly complex die set and die head components, our field also includes machining, deep hole drilling and grinding of a wide range of guide and cooling plates as well as aluminium cooling mandrels.

The many years of experience of our skilled workers in the production of thin-walled turning and milling parts is only a piece of mosaic in the entire production chain.

In our in-house paint shop, our euipment receive the final coating and fine-tuning in the new UNICOR design.

Our assembly team is responsible for the high quality of produced installation lines. Therefore it can be guaranteed that an installation line produced and commissioned in our premises will also be in safe and reliable operation when being installed on your production site.

Due to the variety of our manufacturing machines we even realise short-term delivery times in case of urgent enquiries for spare parts. Our customers really appreciate this positive side effect.

We are not worried about our young talent, because we train young skilled workers year after year in our own apprenticeship workshop. On this occasion our new employees liaise with most different maintenance groups and manufacturing processes at an early stage.