Home » Applications » Infrastructure

Infrastructure

35 years of project experience!

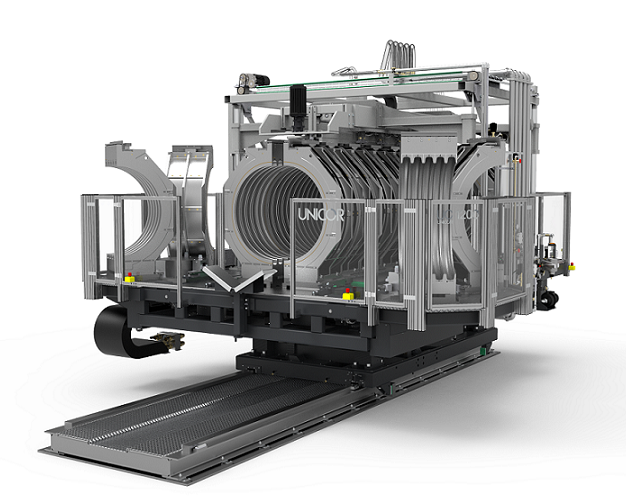

Up to a diameter of 1,800 mm

UNICOR can realise even big-size diameters – double wall corrugated pipes with a diameter of up to 1,800 mm are especially suitable for sewage and drainage applications. Our corugated pipes do not only score with their easy handling but also with their good ecobalance. Resource-saving use of materials with very energy-efficient production.

The infrastructure sector belongs to the main application fields of corrugated pipes and has a 35-year-old tradition at UNICOR. These pipes are very popular with civil engineering companies mainly because of their light weight, high statics and flexibility. The high UNICOR quality standards, especially with regard to the seams, guarantee a longevity of the final product combined with trouble-free coupling of the pipes in the cuff area.

Efficient UNICOR Water Cooling

Equipped with the direct and highly energy efficient UNICOR water cooling and a very low middle channel clearance, premium-quality corrugated pipes are produced. Production parameters are stored by the integrated control technology and product quality can be reproduced at any time.

Besides our standard products we realise individual profil shapes together with our product and process engineers, while complying with a wide range of standards and material specifications. In recent decades, many special solutions have emerged from which each individual customer benefits directly.

Benefits of infrastructure projects

- Easy installation due to low weight (60% lower material expenditure compared to smooth pipes)

- Very robust and durable, resistant to grounding without cracks or leaks (concrete pipes made of rigid material are more prone to cracking)

- High flexibility with high structural strength of the plastic corrugated pipes

- Very high resistance to acids and other aggressive liquids

- Lower material consumption compared to full-wall plastic pipes in a resource-saving

- Better ecological footprint compared to comparable concrete pipes

- Recyclable at the end of the life cycle