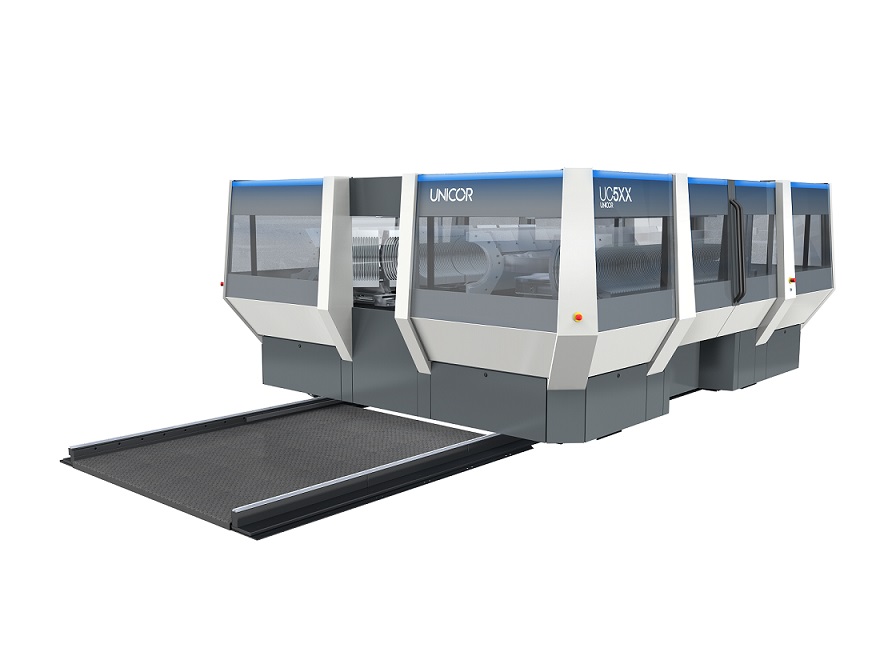

Home » Corrugators » Mid-sized Corrugators » UC 5XX

UC 5XX

The new one

flexible - powerful - efficient

The operating concept, which is standardised across all machines (UC 210/ UC 280/UC 5XX/UC 800), offers optimized machine park and employee utilisation.

Maximum flexibility in the machine park due to compatible mold blocks to the UC 210 and UC 280. Furthermore the UNICOR quick-clamping system ensures an easy and fast mold block change (50% reduction compared to UC 315). This leads to an improved machine availability.

Up to 50% energy savings by speed regulated rotary vane vacuum pumps with only 15 KW connected load.

Perfect quality of the profile surface and profile shape, thus easier processing and higher stability of the corrugated pipe, even with recycled materials. Short dies, lower back pressure and thus higher throughput offer more efficiency and greater flexibility, also in the selection of materials.

- Diameter range 32 – 500 mm i.d.

- Production of cable protection-, drainage- and sewage pipes without loss in productivity

- Compatibility of mold blocks without adapters to the corrugators UC 210 and UC 280

- Different chain length depending on the output requirements

- Maximum production speed of 24 m/min

- Minimal changeover time for mold blocks

- Speed regulated vacuum pumps

- Only 20 °C cooling water inlet temperature necessary

- Electronic control of process air

- Registration and recording of all vacuum parameters

- Registration, recording and electrical control of all water inlet and outlet pressures as well as temperatures

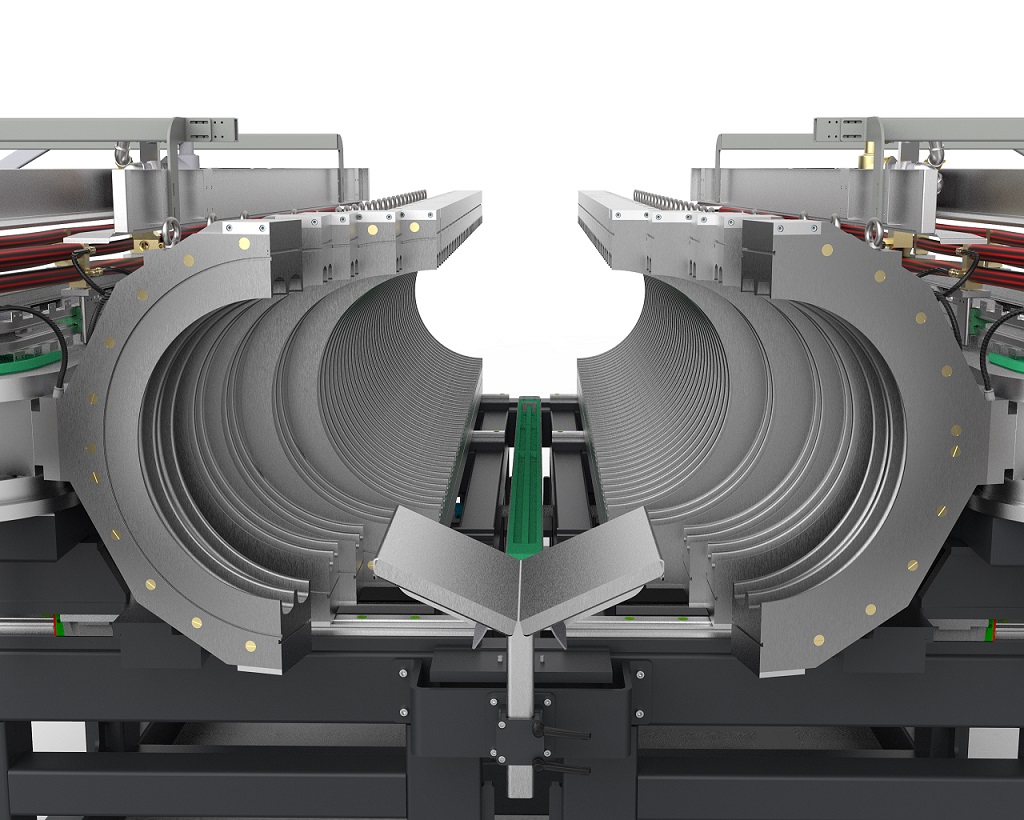

Zoomable middle channel

Due to the zoom capability of the middle channel, pipe size-specific mold blocks can be used. This leads to very short dies and low back pressure. Furthermore, the middle channel can be opened completely for very easy accessibility.

Operating panel

All functions can be selected intuitively on the 15 inch operating panel. The new and improved display provides a much better overview than ever before.